TECHNOLOGY

It might look

simple – but it isn't

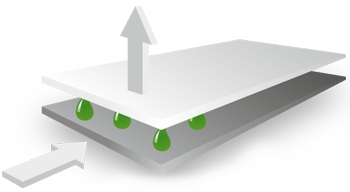

between the layers of a multi-layer system. The liquid breaks this

system up separating it into individual layers. and “burst”

this open, separating the individual layers. However,

the trick is in the “composition” of this magic separation liquid.

Separating composite

materials using

separation liquids

on chemical mixtures for different applications.

The separation liquid channels its way between

the layers of the composite material, where its full effect

unfolds, resulting in the separation of the composite.

The separation

process

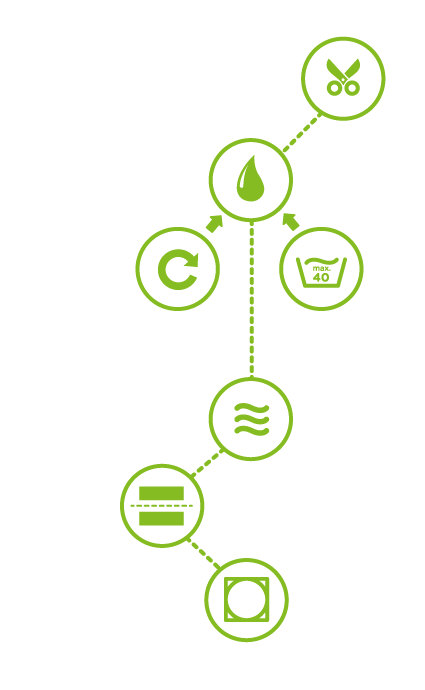

The entire process for recovery of obtaining saleable products <br>from composite waste is as follows:

01 CRUSHING

The first stage is to reduce the size of the material to create as <br>much contact surface for the separation liquid as possible and to <br>simplify material handling during the process.

02 SAPERATEC SEPARATION LIQUID

The core process involves treating the shredded composite material <br>in the separation liquid. The separation process is <br>conducted by stirring and warming up until the individual fractions<br> (“products”) are completely separated.

03 WASHING

First the products are screened out and the separation liquid is<br> reconditioned. Then the products are cleaned from <br>adhesions of chemicals with washing water<br> and the washing water is also reconditioned.

04 SORTING

The now clean products are sorted using conventional procedures<br> (float-sink, sifting, …) and obtained individually.

05 DRYING

Another final drying and occasionally follow-up treatments<br> are required, if necessary, to make the products saleable.

Applications

separation potential

The procedure is a platform technology that can be <br>used for recycling a wide range of materials.

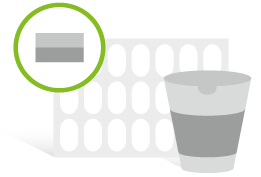

Used beverage cartons

Paper | Plastic | Aluminium

This practical beverage carton that has been used billions

of times is a composite of three different

materials, whereby separating plastic and aluminium in

particular has long been an unresolved challenge.

Packaging material

Aluminium | Plastic

Nowadays packaging should be light and functional. Therefore, it

increasingly consists of several materials. Examples include

packaging for dairy products,

coffee, confectionery, fresh products, cosmetics, pharmaceuticals and even pet food.

PV modules

Glass | Semiconductors | Plastic

The number of PV modules that have been mounted on roofs in just a few years is a real achievement, but at some stage they will become waste. The used raw materials will then have to be recycled. We make this possible by separating modules into individual components.

Li-ion batteries

Aluminium | Lithium metal oxide |

Graphite | Copper

Alongside modern electronics, these high-quality batteries are the driving force

behind electromobility. The valuable

metals such as lithium, aluminium and copper can only be reclaimed when the coiled layers are

separated again.

Car glass

Glass | Plastic

Car glass is a “sandwich” of two panes of glass with an adhesive plastic film in the middle. This film is of very high quality and can be reused after separation, just like the glass.

Something else you want to separate?

Do you have other interesting applications? Or do you have a specific task in mind involving the separation of a

composite material? Then we look forward to hearing from you!

TEAM

Five benefits in

one go

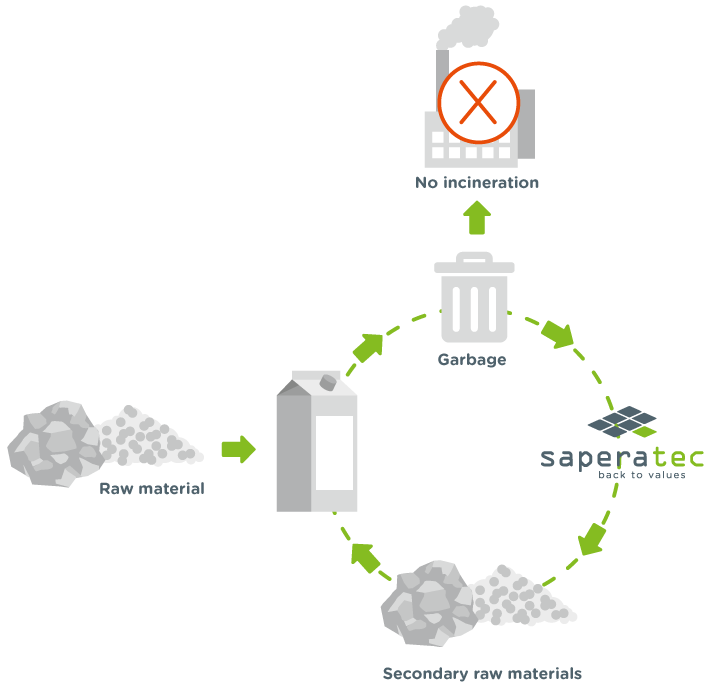

No incineration

Maximum added value

as the used raw materials are recycled

Contribution to environment

due to advantageous eco-balance of the process

High purity

of the obtained raw materials

Reusable

as the separated liquid is<br>reconditioned and reused

Recovery of

raw materials

can be reclaimed as secondary raw materials,

thus fully preserving the cycle of materials – true sustainability!.

This is sustainable.

Win-win

situation

| … due to the sale of valuable secondary raw materials and image enhancement! |

KONTAKT

Sie haben Fragen zu unseren Leistungen oder unseren Service?

Sollten Sie nicht auf Anhieb die gewünschte Leistung finden, helfen wir Ihnen gerne telefonisch oder per E-Mail weiter.

Sie erreichen uns telefonisch unter + 49 340 502 420 – 0 oder über unser Anfrageformular.